SPECIFICATON OF CASTABLES

| PARTICULARS | VRCAST A |

VRCAST K |

VRCAST C |

VRCRETE SUPER |

VRCRETE Normal |

VRCAST 94 |

VRCAST 97 |

VRSET-50 FINE |

| GENERAL PROPERTIES | ||||||||

| Service Temp. °C (Max) | 1750 | 1600 | 1500 | 1450 | 1400 | 1800 | 1850 | 1500 |

| Grain Size mm (Max) | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 | 0.5 |

| Water Required For Casting (%) | 7.5-8.5 | 9.5-10.5 | 9.5.10.5 | 10-11 | 10.5-11.5 | 8.5-9.5 | 8.5-9.5 | 8.5-9.5 |

| CHEMICAL PROPERTIES | ||||||||

| Al2O3(Min.) | 90 | 60 | 50 | 70 | 45 | 94 | 96 | 50 |

| Fe2O3(Max.) | 0.8 | 1.0 | 1.30 | 5.0 | 4.0 | 0.3 | 0.3 | 4.0 |

| PHYSICAL PROPERTIES | ||||||||

| Bulk Density (gm/cc) (Dried at 110 °C for 24 hrs.) (Min.) |

2.75 | 2.20 | 2.10 | 2.50 | 2.10 | 2.80 | 2.80 | - |

| Cold Crushing Strength (kg/cm2) 110°C | 600 | 350 | 350 | 350 | 250 | 600 | 400 | - |

| THERMAL PROPERTIES | ||||||||

| Refractoriness Under Load °C (Min.) |

1820 | 1683 | 1665 | 1683 | 1564 | 1835 | 1835 | 1835 |

| Permanent Linear Change (%) | ±1.00 | ±1.50 | ±1.00 | ±1.00 | ±1.00 | ±0.50 | ±0.80 | - |

NOTE: We can Manufacture and supply any related product as per customers specification.

INSULATING CASTABLES

| PARTICULARS | VRLYTE 4 |

VRLYTE 7 |

VRLYTE 9 |

VRLYTE 11 |

VRLYTE 13 |

VRLYTE 15 |

| GENERAL PROPERTIES | ||||||

| Service Temp. °C (Max) | 1000 | 1100 | 1200 | 1300 | 1350 | 1350 |

| Grain Size mm (Max) | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 |

| Water Required For Casting (%) | 80-100 | 60-65 | 38-43 | 39-34 | 26-31 | 23-28 |

| CHEMICAL PROPERTIES | ||||||

| Fe2O3(Max.) | 11.00 | 8.50 | 6.00 | 3.50 | 3.50 | 3.20 |

| PHYSICAL PROPERTIES | ||||||

| Bulk Density (gm/cc) (Dried at 110°C for 24 hrs.) (Min.) |

550 | 850 | 1000 | 1250 | 1450 | 1600 |

| Cold Crushing Strength (kg/cm2) 110°C | 4 | 12 | 15 | 35 | 50 | 90 |

| 800°C | 2 | 4 | 5 | 25 | 30 | 60 |

| 1000°C | - | 6 | 10 | 25 | 30 | 60 |

| THERMAL PROPERTIES | ||||||

| Refractoriness Under Load °C (Min.) |

- | 1340 | 1400 | 1400 | 1400 | 1430 |

| Permanent Linear Change (%) 800°C |

±0.40 | ±0.80 | ±0.60 | - | - | - |

| 1100°C | ±0.60 | ±1.20 | - | ±0.20 | ±0.20 | ±0.20 |

| 1300°C | - | - | - | ±1.00 | ±0.80 | ±1.00 |

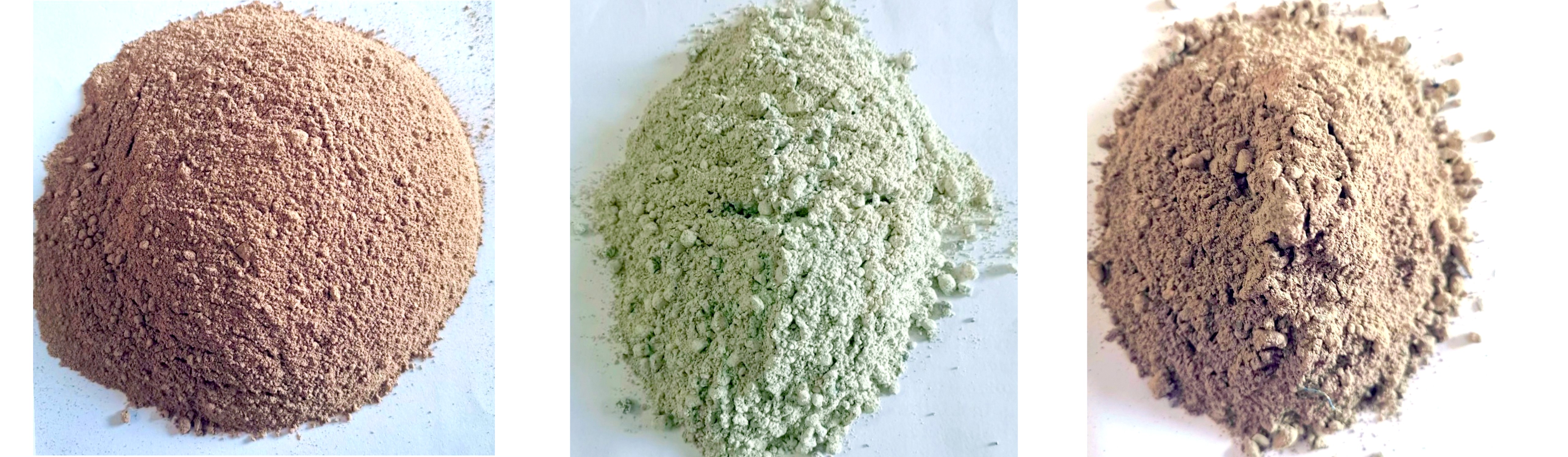

MOROTARS

| PARTICULARS | Al2O3(%) | Fe2O3(%) | PCE Orton Cone °C |

Service Temp (°C) | Application Area |

| VR Mortar IS-6 | 22.0 | 2.5 | 20/1564 | 1350 | For laying of 30% Al2O3 bricks |

| VR Mortar-40 | 38.0 | 2.8 | 31/1683 | 1450 | For laying of 40% Al2O3 bricks |

| VR Mortar-50 | 48.0 | 3.0 | 32/1717 | 1500 | For laying of 50% Al2O3 bricks |

| VR Mortar-60 | 55.0 | 3.5 | 33/1743 | 1550 | For laying of 60% Al2O3 bricks |

| VR Mortar-70 | 65.0 | 3.5 | 34/1763 | 1600 | For laying of 70% Al2O3 bricks |

| VR Mortar-80 | 75.0 | 2.5 | 36/1804 | 1700 | For laying of 80% Al2O3 bricks |

| VR Mortar Sill | 55-52 | 1.5 | 34/35 | 1450 | Ceramic |